China Machinery Group for Materials & Equipments Co., Ltd.

| Parameter\Model | HVGQ-446D | HVGQ-557D | HVGQ-669D | HVGQ-7711D | HVGQ-8810D | HVGQ-8812D | HVGQ-9915D |

| Effective hot zone size W×H×L (mm) | 400 × 400 × 600 | 500 ×500 × 700 | 600 × 600 × 900 | 700 × 700 × 1100 | 800 × 800 × 1000 | 800 × 800 × 1200 | 900 × 900 × 1500 |

| Loading capacity (kg) | 250 | 400 | 600 | 1000 | 1100 | 1200 | 1500 |

| Heating power (kW) | 75 | 90 | 150 | 270 | 360 | 390 | 480 |

| Max. temperature (°C) | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 |

| 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Temperature uniformity (°C) | ±5 | ±5 | ±5 | ±5 | ±5 | ±5 | ±5 |

| Vacuum degree (Pa) | 4 × 10-1 | 4 × 10-1 | 4 × 10-1 | 4 × 10-1 | 4 × 10-1 | 4 × 10-1 | 4 × 10-1 |

| 1 × 10-3/5 × 10-4 | 1 × 10-3/5 × 10-4 | 1 × 10-3/5 × 10-4 | 1 × 10-3/5 × 10-4 | 1 × 10-3/5 × 10-4 | 1 × 10-3/5 × 10-4 | 1 × 10-3/5 × 10-4 | |

| Pressure increasing rate (Pa/h) | ≤0.26 | ≤0.26 | ≤0.26 | ≤0.26 | ≤0.26 | ≤0.26 | ≤0.26 |

| ≤0.65 | ≤0.65 | ≤0.65 | ≤0.65 | ≤0.65 | ≤0.65 | ≤0.65 | |

| Transportation time (S) | ≤15 | ≤20 | ≤25 | ≤30 | ≤30 | ≤30 | ≤35 |

| Gas quenching pressure (bar) | 6/10/15/20/ 40/60 | 6/10/15/20/ 40/60 | 6/10/15/20/ 40/60 | 6/10/15/20/ 40/60 | 6/10/15/20/ 40/60 | 6/10/15/20/ 40/60 | 6/10/15/20/ 40/60 |

| Cooling gas (99.995%) | N2/Ar/He | N2/Ar/He | N2/Ar/He | N2/Ar/He | N2/Ar/He | N2/Ar/He | N2/Ar/He |

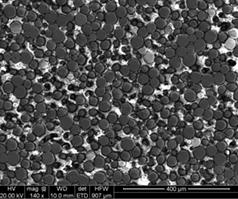

Tag: Powder Metallurgy of Titanium Alloys | Titanium Powder Metallurgy | Titanium Alloy Powder Material | TC4(Ti-6Al-4V)Titanium-based Alloys Powder

Tag: Vertical Bottom Loading Vacuum Annealing Furnaces | Vertical Vacuum Bottom Loading Annealing Furnace | Bottom Loading Vacuum Annealing Furnace